Cherton: delivering outcomes through effective engagement

Delivering project success

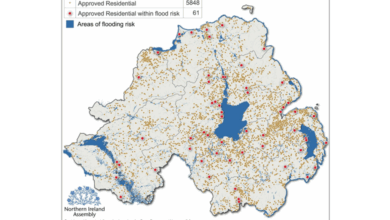

The Northern Ireland marketplace has distinctive legacy issues arising from its recent history and its unique political, community, government and administrative structures.

The Northern Ireland marketplace has distinctive legacy issues arising from its recent history and its unique political, community, government and administrative structures.

Building value or delivering a major project is always challenging and it pays to have the best advisors. Cherton has a proven track record and the ability to help you deliver the most effective way of getting your plans and projects, from launch to delivery.

Cherton is one of Northern Ireland’s leading Strategic Public Affairs companies, specialising in providing strategic advice and active support to individuals, companies and organisations seeking to create or develop business and value within the local market.

The company’s knowledge and experience has been gained dealing almost entirely with the delivery of major, largely private sector, commercial projects. It has also advised local government on the delivery of major projects and associated fund-raising challenges, key elements of local economic development plans.

Through working at lead executive, CEO and Board level and focusing and managing effective engagement at the highest levels of government and the public sector, Cherton adds significant value to the potential for success of client business plans, its principals are recognised as trusted professionals in this field and success has been our measure. Professional advice will range across all key success areas such as local communities, customer groups, commerce, politics and administrative structures.

Through detailed engagement with clients, we will learn: about your business, the environment in which you work and engage and what you strive to achieve. Cherton will identify the impediments to and the opportunities for your plans: build relationships with your key stakeholders based on trust and integrity: develop opportunities through clear positive messages and focused communication, matching these where applicable to public sector policies and political objectives and then monitoring and managing the process and progress of the project. We know that for driven companies and executives, time and resource is precious – we don’t want to waste it.

Best success is rarely achieved through a quick fix. More often it’s a medium to long-term strategy supporting a business plan, offers the best potential of success. The best outcomes come from the fullest integration of Cherton into the client team. This allows for early identification of potential issues and opportunities and the greatest chance of minimising the impact of potential threats and maximising the benefits of positive opportunities. It also allows for the early development of key team relationships based on trust and respect.

Cherton also has invaluable experience in “addressing local issues”. Engaging communities, customer and single issue groups across a wide spectrum of issues is often an essential part of delivering business objectives and we are recognised as a leader in this field.

At Cherton we are committed to adding value to client company businesses, whether already trading locally or considering entry to the local market. We would welcome the opportunity of exploring how our particular capabilities could be a match to your corporate aims and goals.

Why not get in touch and we will be happy to tell you in more detail, about ourselves, our service, the Northern Ireland marketplace and how to achieve your best local outcomes?

Contact us by email karen.hughes@cherton.co.uk

Contact us by email karen.hughes@cherton.co.uk

Or call us on 028 9076 9966

www.cherton.co.uk