Constituency changes for Northern Ireland’s elections

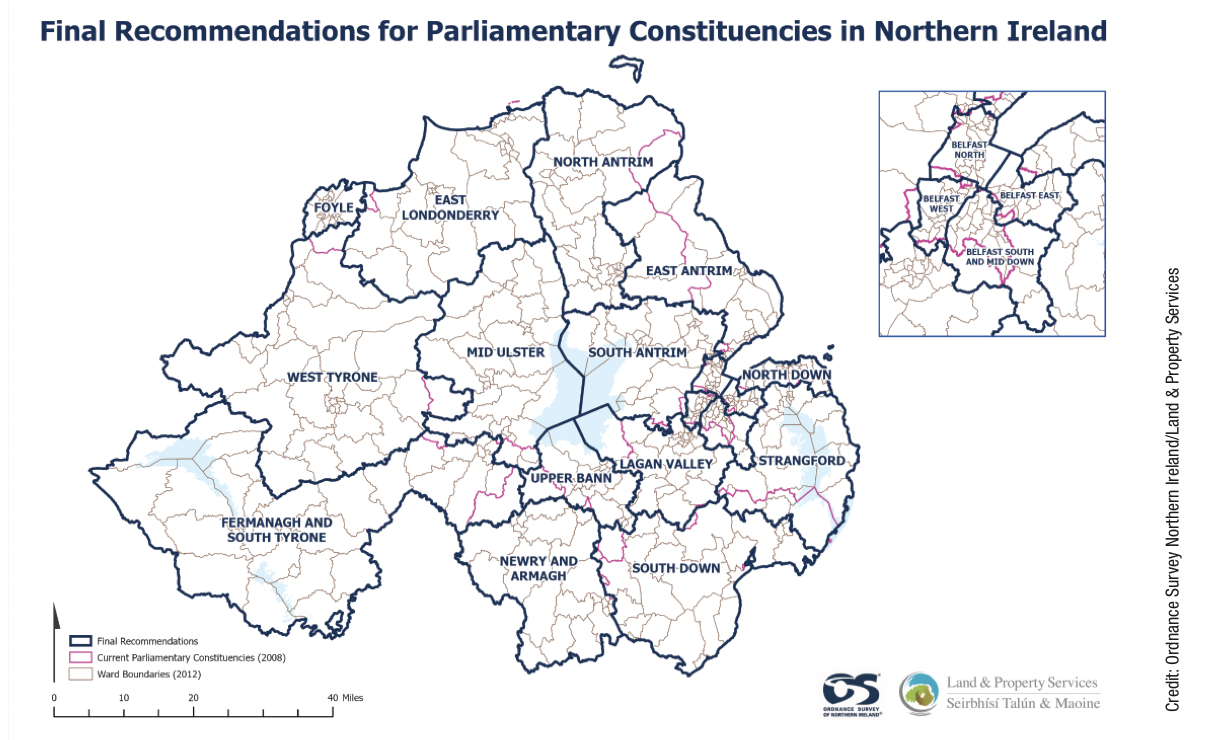

A review by the Boundary Commission means that all of Northern Ireland’s parliamentary constituencies will be revised, with one to be renamed.

The final review, published at the end of June 2023, has recommended that the constituency of Belfast South be abolished, with the area to be re-shaped into a new constituency of Belfast South and Mid Down. The changes are likely to be in effect before the next UK general election, which is expected to take place in autumn 2024.

The proposed changes will also apply to elections to the Northern Ireland Assembly, as Section 33 of the Northern Ireland Act 1998 provides that Assembly members shall be returned for the parliamentary constituencies in Northern Ireland.

Originally, the Boundary Commission released a report in October 2021 which recommended dramatic changes to Northern Ireland’s constituencies, including a reduction from the current total of 18 down to 17, with the Commission stating at the time that 11 of Northern Ireland’s 18 constituencies were either too big or too small.

In October 2022, the Boundary Commission, following an eight-week consultation for the initial proposal in 2021, dropped the renaming of various constituencies including Strangford and Upper Bann, and further dropped the proposal to reduce the number of constituencies in Northern Ireland.

With the consultation now complete from the October 2022 proposals, the current report makes it clear that the number of constituencies in Northern Ireland will remain the same, but which did re-shape a number of constituencies, including Strangford and Upper Bann, as well as the renaming of the Belfast South constituency.

New Belfast boundaries and other changes

By far the most dramatic development of the boundary review is the renaming and reshaping of the Belfast South constituency. The new Belfast South and Mid Down constituency will encompass most of the current Belfast South constituency, along with parts of the current manifestations of the constituencies of Belfast East, Strangford, and South Down.

The proposal for the changes to the current Belfast South constituency will have an undoubted change in the political makeup of the constituency at the next election due to demographic changes which will occur as a result, although it is unclear as to which party will benefit as a result.

The new proposals also mean that County Down will be split into seven different constituencies. These are: North Down, Strangford, Belfast East, Belfast South and Mid Down, Newry and Armagh, Upper Bann, and South Down. The majority of these constituencies also contain parts of other counties.

Additionally notable is the reshaping of the constituencies of East Antrim and Strangford. Although both of these constituencies will retain their current names, the change in their boundaries – with wards just outside Downpatrick now forming part of Strangford rather than South Down – will forge likely demographic changes which may change the political outcomes from the voters of these constituencies.

A decade-long journey

The UK Boundary Commission carries out reviews of constituencies for elections to the House of Commons every 10 years. Previously, dramatic changes have occurred in Scotland, where in 2005, the number of constituencies was reduced from 72 in the 2001 general election to 59 in the 2005 election.

Following the formation of the Conservative-Liberal Democrat coalition in 2010, then-Prime Minister David Cameron outlined plans to reduce the number of seats in the House of Commons to 600, down from 650, as an anti-politics sentiment gripped the British public amid the expenses scandal and the austerity policies being pursued by the coalition government.

The British parliament passed the Parliamentary Voting System and Constituencies Act 2011, which legally obliged the House of Commons to be fixed at 600 MPs. However, the passage of the Electoral Registration and Administration Act 2013 delayed the publication of the Boundary Commission’s report, which would have implemented the size reduction, with Section 6 of the Act postponing the Sixth Periodic Review until “not before 1 October 2018”. Therefore, the 2017 and 2019 general elections were also contested without the changes recommended by the Cameron government.

The current government, when Boris Johnson was the Prime Minister, subsequently dropped the reform agenda and cancelled many of the reforms proposed under the coalition government with the passage of the Parliamentary Constituencies Act 2020. This measure cancelled the proposal to reduce the number of MPs, and also ended the Fixed-term Parliaments Act 2011, allowing the House of Commons to be reduced with a simple majority and the advice and consent of the monarch of the UK.

Having been presented to Parliament by the Speaker of the House of Commons in accordance with the Parliamentary Constituencies Act 1986 (as amended), the Government must now submit a draft order in council within four months, giving effect to the recommendations in the report. The proposal is expected to be passed by MPs and come into effect on 1 November 2023.